- ABOUT CTC

- EXPERTISE AND SERVICES

- Raw hide - Tannery

- Footwear

- Leather goods - Glove-making

- PPE

- Environment

- CSR

- Training

- Safety of articles with ICARE

- BLOG AND NEWS

- CTC VIDEOS

- LEAFLETS AND PUBLICATIONS

- CUSTOMERS EXTRANET

EN

Leather traceability is a major challenge and priority for all stakeholders in the leather industry. To help, CTC brings you its “traceability solution”, from the birth of the animal to the cutting of the leather.

In France, as in most European countries, meat traceability is a legal requirement. Each animal is given a unique identification tag as soon as it is born. This identifier accompanies the carcass from slaughter to butchering. However, traceability is lost when this identifier is separated from the skin during the flaying process. A solution was needed to transfer this information onto the skin in such a way that it would remain intact throughout the tanning process.

CTC tested a host of technologies to address the issue of end-to-end traceability, including RFID glass tag insertion, dot peen marking, chemical marking (DNA, tracers), and all types of labels.

ALIS MARKING is the solution that emerged as the clear winner.

To date, the laser marking technology developed by CTC remains the only reliable solution for guaranteeing the traceability link between the abattoir and the tannery.

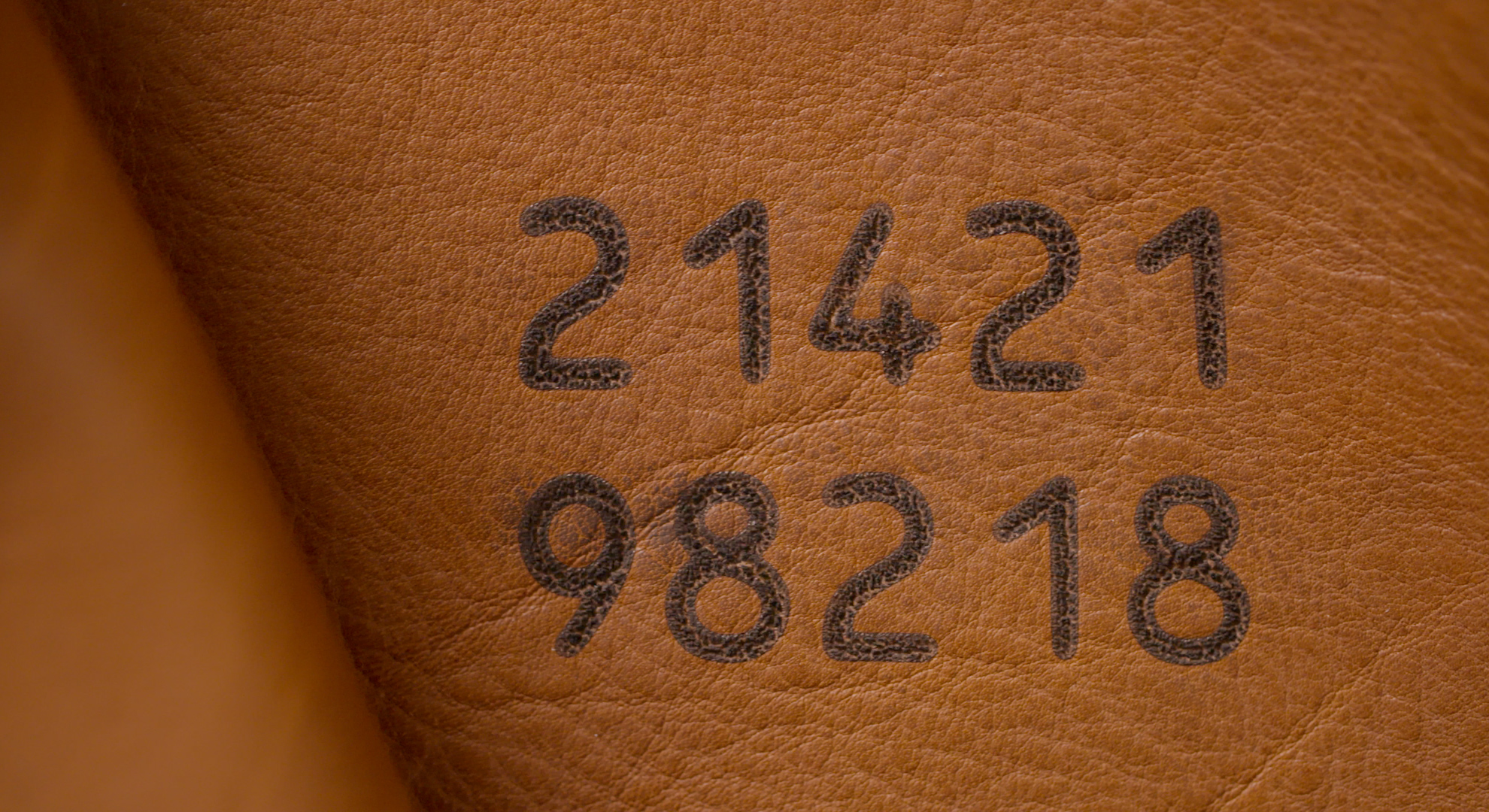

CTC’s solution, called ALIS MARKING (where ALIS stands for Automatic Leather Identification System), consists of a CO2 laser marking system that engraves a unique code directly into the skin prior to the wet-work/tanning process.

This system is protected by European Patent EP3269829.

It uses:

The CO2 gas laser, the most suitable type for marking organic materials, is a reliable technology that has been used and mastered in other industries for over 20 years.

This contactless marking system can be seamlessly integrated into existing salting plant processes, without slowing down the production line or requiring an additional workstation. Indeed, the laser offers great flexibility and guarantees high speed thanks to its power.

Last but not least, safety is a major advantage of this technology. The beams are perfectly confined and the fumes are extracted at the source to avoid odours in the workshop and, above all, to ensure the safety of the operators.