CTC, specialist of PPE test and certification, first Notified Body (n°0075) in Europe to deliver CE type-examination certificates, with more than 38,000 CE type-examination certificates delivered under the 2016/425 regulation.

Obligations are fixed in the PPE users” Directive 89/656 dated 30.11.1989 and the associated texts.

Employers of people using PPE must insure that they analyse and assess, in collaboration with the various internal committees, the weaknesses of the protection systems.

In accordance with the definition above, they select personal protective equipment with the appropriated level of protection necessary in view of the potential danger and risk likely to be incurred.

They provide personal protective equipment free of charge and conforming to the legal requirements, i.e.:

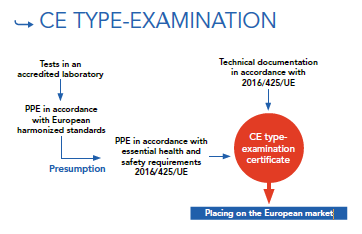

CE marking is based on the following texts: “PPE design” Regulation 2016/425/UE

Manufacturers must place PPE gloves on the market that comply with the essential requirements of European Regulation 2016/425/EU.

For this purpose, they are required to:

1- Characterize the level of risks against which their protective glove will protect its user. It will define the certification rules (see A).

2- Define all risks precisely. It will set all necessary standards during the certification process (see B) .

3- The manufacturer will choose his Notified Body, CTC. Most protective gloves (see C) are in category II. For category III PPE gloves, an annual control system must be defined (module C2 with CTC or module D with another Notified Body).

4- The manufacturer shall send to the Notified Body a technical file containing :

5- Once the Notified Body has issued an EU type-examination certificate number, the manufacturer shall:

|

Certification rules |

Category I | Category II | Category III |

| CLASSIFICATION | Minor risks | Other risks | Lethal or irreversible risks |

| EXAMPLES |

Gardening glove |

Glove for mechanical risks |

Glove for chemical risks |

|

OBLIGATIONS OF THE MANUFACTURER |

|

Category I +

|

Category II +

|

ANSI/ISEA 105 |

Hand Protection Classification |

EN ISO 374-1 |

Protective gloves against dangerous chemicals and microorganisms - Part 1: Terminology and performance requirements for chemical risks |

EN ISO 374-5 |

Protective gloves against dangerous chemicals and microorganisms - Part 5: Terminology and performance requirements for micro-organisms risks |

EN 388 |

Protective gloves against mechanical risks |

EN 407 |

Protective gloves against thermal risks (heat and/or fire) |

EN 421 |

Protective gloves against ionizing radiation and radioactive contamination |

EN 511 |

Protective gloves against cold |

EN 659 |

Protective gloves for firefighters |

EN 1082 |

(part 1 to 3) Protective clothing - Gloves and arm guards protecting against cuts and stabs by hand knives |

EN ISO 10819 |

Mechanical vibration and shock - Hand-arm vibration - Measurement and evaluation of the vibration transmissibility of gloves at the palm of the hand |

EN ISO 11393-4 |

Protective clothing for users of hand-held chain-saws - Part 4: Test methods and performance requirements for protective gloves |

EN 12477 |

Protective gloves for welders |

EN 13594 |

Protective gloves for motorcycle riders - Requirements and test methods |

EN ISO 13997 |

Protective clothing - Mechanical properties - Determination of resistance to cutting by sharp objects |

EN 14328 |

Protective clothing - Gloves and armguards protecting against cuts by powered knives - Requirements and test methods |

EN 16027 |

Protective clothing - Gloves with protective effect for association football goal keepers |

EN 16350 |

Protective gloves - Electrostatic properties |

EN 16523 |

(parties 1 et 2) Determination of material resistance to permeation by chemicals |

EN 16778 |

Protective gloves - The determination of Dimethylformamide in gloves |

EN 18889 |

Protective gloves for pesticide operators and re-entry workers - Performance requirements |

EN ISO 21420 |

Protective gloves - General requirements and test methods |

Since 1992, CTC is one of the earliest Notified Bodies for PPE with number 0075. We have issued more than 35,000 CE certificates for safety footwear, protective gloves and protective garments. The skill for testing and certification is guaranteed by the ISO 17025 and ISO 17065 accreditation.

The professionalism and the accuracy of our physical and technical tests help our customers to produce the safest footwear and glove product. We test and certify at the same time, so you save time.

CTC has a large experience of the innocuousness testing in materials and products. The European legislation is the most severe legislation in the world. CTC will help you to define the right critical substances to test. The integration of safety requirements will enable you to guarantee the conformity of the products according to Annex XVII of REACh.

CTC is Convenor or member for the mains standardization technical committees for glove, footwear and garment.

|

|

|

|

CTC Shanghai et CTC Dongguan CTC Shanghai : CNAS L4577 CTC Dongguan : CNAS L5912 |

CTC Asia, |

NEED ASSISTANCE ? CONTACT US !

NEED ASSISTANCE ? CONTACT US !

|

MECHANICAL RISKS EN 388 - WXYZα (P) |

COLD RISKS EN511 - XYZ |

CHEMICAL RISKS EN ISO 374-1 |

|

|

|

|

|

Permeation resistance + letters corresponding to the tested chemical

|

|

IMPACT CUT EN 1082 |

MICRO-ORGANISM HAZARDS EN ISO 374-5 |

THERMAL RISKS EN 407 - UVWXYZ |

|

|

|

|

|

|

|

|

|

RADIOACTIVE CONTAMINATION EN 421 |

HEAT AND FIRE HAZARDS FOR FIREFIGHTERS - EN 659 |

|

|

|

|

|

|

HAND HELD CHAINSAWS EN ISO 11393-4 |

MOTORCYCLE RIDERS EN 13594 |

|

|

|

|

|

INFORMATION |

PESTICIDES RISKS EN ISO 18889 |

|

|

|

|